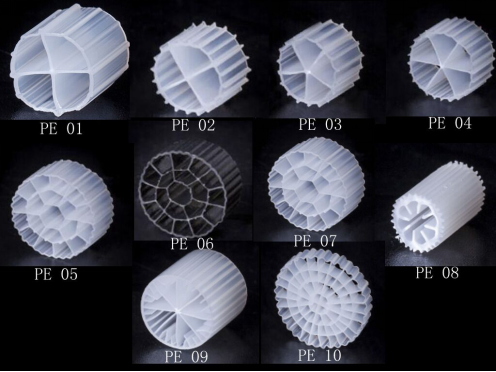

Product List

Moving Bed Biofilm Reactor(MBBR) is a moving media system, used in integrated fixed-lm activated sludge (IFAS) and moving bed biofilm reaction (MBBR) system, and MBBR media is the key in the system.

-

Description

Moving Bed Biofilm Reactor(MBBR) is a moving media system, used in integrated fixed-lm activated sludge (IFAS) and moving bed biofilm reaction (MBBR) system, and MBBR media is the key in the system. In the MBBR biofilm technology, the biofilm grows protected within engineered plastic media, which are carefully designed with high internal surface area.

These bio filter media are suspended and thoroughly mixed throughout the water phase. With this technology, it is possible to handle extremely high loading conditions without any problems of clogging, and treat industrial and municipal wastewater within a relatively small footprint.

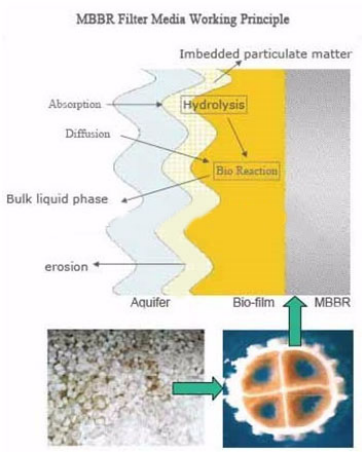

Principle:

The suspended medias as carrier for the growth and attachment of microorganisms are directly put into the MBBR system. The waste water go through the suspended carriers in MBBR reactor, microorganisms attach themselves to submerged moving biofilm carrier, forming a biofilm. Air is transferred into the water, mixing the media and water and providing oxygen to the bacteria. The biofilm absorbs, oxidizes and reduces organic and inorganic material thus providing treatment.The carriers can move freely in the reactor with the mixing of the water; for the aerobic reactor, the aeration will make the media move; for the anaerobic reactor, mechanic mixing will make the media move.

-

Applications

• Excess load active sludge process treatment plant transformation.

• Newly built sewage treatment factory of MBBR and BAF process.

• Biological treatment of wastewater reuse.

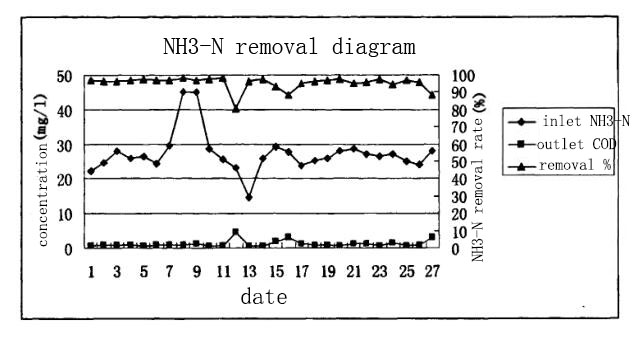

• River regulation, denitrification and phosphorus removal.

• Aquaculture degrade ammonia nitrogen, water purification.

• As biological deodorization tower filler.

-

Technical parameters

Model

PE01

PE02

PE03

PE04

PE05

PE06

PE07

PE08

PE09

PE10

Size(mm)

12*9

11*7

10*7

16*10

25*10

25*10

35*18

5*10

15*15

25*4

Hole numbers(pcs)

4

4

5

6

19

19

19

7

40

64

Surface area(m2/m3)

>800

>900

>1000

>800

>500

>500

>350

>3500

>900

>1200

Density(g/cm3)

0.96-0.98

0.96-0.98

0.96-0.98

0.96-0.98

0.96-0.98

1.02-1.05

0.96-0.98

1.02-1.05

0.96-0.98

0.96-0.98

Dosing ratio(%)

15-67

15-68

15-70

15-67

15-65

15-65

15-50

15-70

15-65

15-65

Biofilm-forming time(days)

3-15

3-15

3-15

3-15

3-15

3-15

3-15

3-15

3-15

3-15

Suitable temperature(℃)

5-60

5-60

5-60

5-60

5-60

5-60

5-60

5-60

5-60

5-60

Service life(years)

>20

>20

>20

>20

>20

>20

>20

>20

>20

>20

-

Advantages

1.geometricconfiguration based on hydrodynamics to strengthen the surface adhesive ability. it is polymer material, having high shock resistance.

2.large specific surface aera, many adhesive biologia.It not only provides the room for heterotrophic bacteria growing but also create the condition for autotrophic bacteria growing. Meanwhile, it is beneficial for the biologia to denitrification and dephosphorization.

3.no need of bracket, easy to fluidify, save energy consumption.The suitable specific weight makes the filler in suspended fluidization state, reducing the eneray consumption and increasing the shock and cutting of bubbles. In the same condition, the aeration amount can be lowered by above 10%.

-

Related Products